Uniaxial compressive strength (UCS) test

Hardness is the basic quantitative engineering property of a rock sample. Assessing the strength and deformability of rock mass is of great importance for the implementation of numerical analyses in rock mechanics.

Uniaxial compressive strength (UCS) is a geomechanical rock parameter that describes the maximum axial load that the sample can withstand without lateral loading. This is why it is also called unlimited compressive strength.

The rock is sampled by core drilling, and the sample that best represents the rock mass is selected. The minimum diameter of the sample is 47 mm, and it is 10 times larger than the largest grain in the sample. The ratio of length to diameter of the sample (L/D) must be between 2 and 2.5 according to the ASTM (American Society for Testing and Materials) standard, and between 2.5 and 3 according to the ISRM (International Society for Rock Mechanics) standard.

Cylindrical surfaces are prepared by grinding to make them flat and smooth. The ends of the sample must be leveled within a tolerance of 0.02 mm, with the vertical axis within 0.06 degrees. The load on the sample should be applied continuously, in such a way that failure occurs within 5 to 10 minutes from the start of stress. Continuous load increase is from 0.5 to 1 MPa.

The device used in uniaxial compressive strength testing consists of the following parts:

- a force applying compression machine that constantly applies the required force at a given speed until the end of the test (picture 1);

- pressure plates, steel plates that are used to transfer the axial load to the ends of the sample. They must be made of hardened steel with a minimum hardness of Rockwell 58 (“C” scale). The contact surfaces do not deviate from the plane by more than 0.015 mm when the plates are new and they are maintained within the permissible variation of 0.025 mm;

- stress measuring devices.

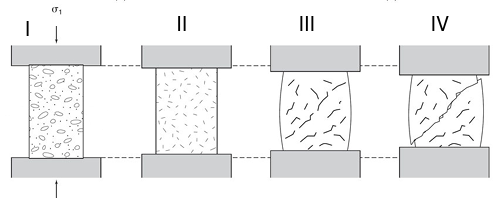

After it is placed in the testing device, the sample is loaded with an axial force. Stress is measured simultaneously.

The compressive strength of the test sample is determined according to the following equation:

where σ is the uniaxial compressive strength in MPa, P is the force failure in kN, and A is the sample area in mm2.

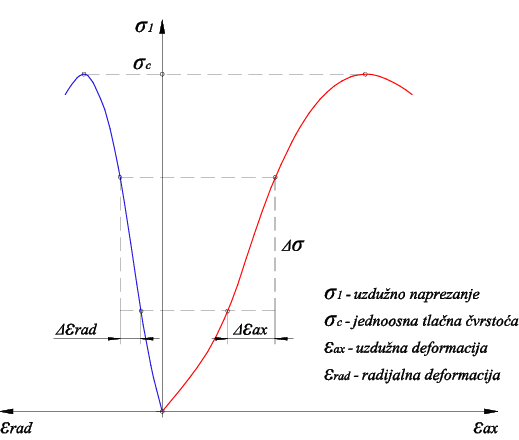

Axial and radial deformation (εax i εrad) are terms that refer to the changes in the height and diameter of the sample due to the applied load, and these are measured using a displacement sensor during the test.

Figure 2. shows the deformation curves for uniaxial stress.

(http://geotehnika.weebly.com/uploads/7/3/0/4/7304689/geolab_3.predavanje.pdf)

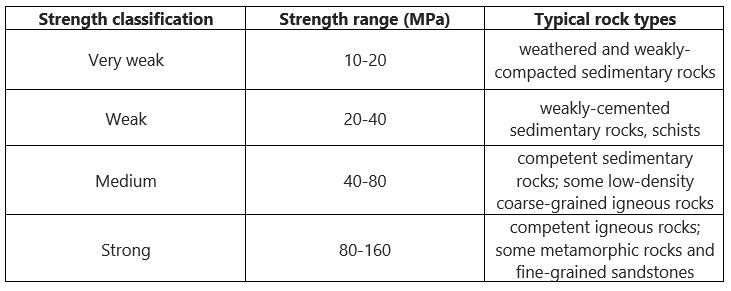

With regard to the uniaxial compressive strength, the rock can be classified as very weak to strong according to the following scale:

In most sedimentary rocks uniaxial compressive strength increases with the age of the rock due to a larger degree of lithification and decreased porosity.

It is worth mentioning that this test cannot fully replicate the actual rock strength because it does not take into account in situ factors such as discontinuities, faults and wear on a larger scale. However, in-situ rock mass testing is rarely practical or economically possible, and uniaxial compressive strength testing is a simple and widespread test that can, through a standardized procedure, generate values we consider representative.

*References:

ASTM D7012-14e1, (2014). Standard Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of Stress and Temperatures, ASTM International, West Conshohocken, PA.

Attewell, P.B. and Farmer, I.W. (1976). Principles of engineering geology. Chapman and Hall, London.

https://www.geoengineer.org/education/laboratory-testing/unconfined-compression-test

http://geotehnika.weebly.com/uploads/7/3/0/4/7304689/geolab_3.predavanje.pdf

https://www.grad.unizg.hr/_download/repository/GI_6.predavanje__Cvrstoca_stijenske_mase.pdf

http://rgn.hr/~smihalic/nids_snjezanamihalic/08_poglavlje.pdf

https://www.usb.ac.ir

Read more: Grain size analysis, Direct shear, Oedometer soil test