Direct shear

Taking into account the intended function and the client requirements, each building is evaluated to anticipate its performance in order to ensure the safety of its future users. This applies to both the building itself and the foundation soil. The permissible loads and deformations are taken into account—these will depend on the structure and the conditions provided by the soil, but also on the interaction between the building and the foundation soil.

Stresses and deformations in the soil lead to a state of instability, such as failure. A failure is manifested as the sliding of one soil mass over another over a sliding surface or sliding zone. In the area of the sliding surface, the stress exceeded the shear soil strength, i.e., the maximum shear stress that the soil can withstand before failure.

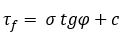

In order to determine the value of the shear soil strength, the Mohr–Coulomb law of failure is used in soil mechanics. It defines the shear strength of the soil by the following equation:

where:

- σ – the normal stress

- c and φ – the strength parameters

- c – cohesion

- φ – the angle of internal friction

This equation defines a direction called the fracture envelope, and the circle that touches it corresponds to the stress state at the point where the failure occurs.

The shear soil strength is determined by laboratory testing of direct shear, triaxial testing in a triaxial (axial) device, uniaxial testing and wing probe testing.

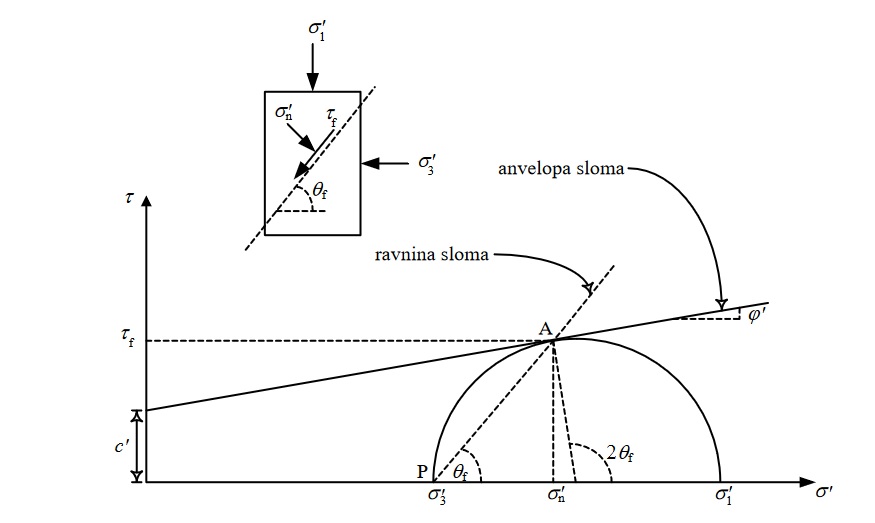

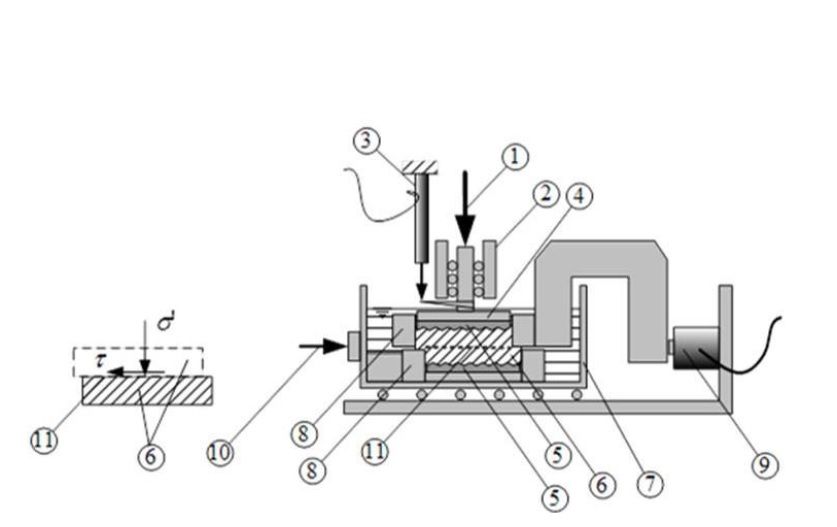

Direct shear device

A direct shear or direct shear device is a laboratory device for testing soil strength under drained conditions. The test is performed in two phases: consolidation under vertical load and shear.

The undisturbed sample is installed between two porous plates in a two-part steel box. During vertical loading, the settlements of the upper sample cap are recorded over time. When the consolidation is complete, the time required to achieve consolidation is determined from the resulting consolidation curve. From this data, the minimum shear rate is determined, which depends on the drainage conditions, permeability and thickness of the sample, and which in the second phase ensures that the effective stresses in the sample are equal to the total stresses.

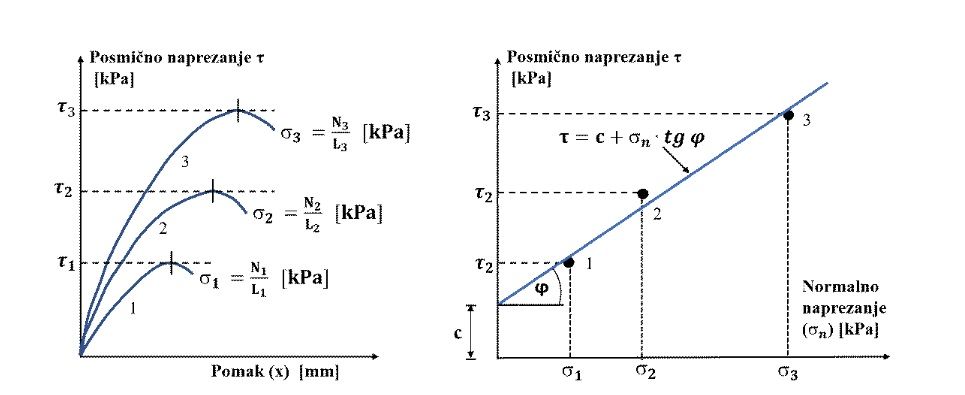

After the vertical deformation subsides, shear is induced. The top and bottom of the box move horizontally relative to each other. The deformation of the sample is concentrated in the area around the horizontal plane between the two parts of the box. As a rule, three tests are performed on the same soil at different vertical loads.

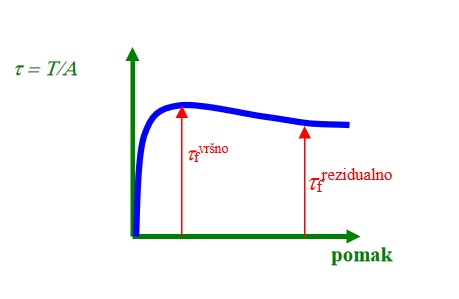

We distinguish between peak strength as the highest value of shear stress characteristic of minor deformations and plastic failure, and residual or permanent strength as a constant value of stress at large deformations and brittle-plastic failure.

The test results are shown in three diagrams—a settlement time flow curve, the ratio of shear stress and horizontal deformation, and peak shear stresses and associated vertical stresses.

Direct shear is a simple and fast way to determine the parameters of shear strength, cohesion and internal friction angle. However, it is necessary to select the test conditions that will best approximate the actual condition of the sample. This includes soil characteristics, drainage conditions, the amount of vertical stress and shear rate.

*References:

Bek, A. (2020.): Utjecaj brzine smicanja na posmičnu čvrstoću tla, Završni rad, Geotehnički fakultet Sveučilišta u Zagrebu

Szavits-Nossan, V. (2014.): Mehanika tla i stijena – 7. predavanje, Građevinski fakultet Sveučilišta u Zagrebu

Zlatović, S. (2006.): Uvod u mehaniku tla – udžbenik Tehničkog veleučilišta u Zagrebu, ISBN 953-7048-02-0

https://theconstructor.org/geotechnical/shear-strength-soil-direct-shear-test/3112/

Read more: Laboratory testing of rock mass strength