Foundation remediation with jet grouting

Jet grouting

Jet grouting is one of the technologies of foundation remediation.

Foundation remediation of the buildings that are in function is very complex and it is necessary to adjust the technology to the conditions on site.

Jet grouting is a soil improvement method that converts a certain volume of soil into a mortar, breaking down the soil structure using high energy fluid jets. Simultaneously, the soil particles are mixed with the cement suspension and fill the affected area. Excess of mixture flows along the opening of the borehole to the surface.

Jet grouting columns are performed to ensure the load transfer of the building into deeper layers (bedrock or deeper layers of better bearing capacity) and eliminate further displacement and differential settlements.

Injecting underneath the existing foundations performs reinforcement of the soil which is actually deepening of the foundations.

Jet grouting columns are analogous to the piles, and by inclined columns, it is possible to transfer to the ground horizontal forces that appear in the foundation.

Equipment for jet grouting is characterized by uniform rotational speed of injection as well as lifting speed. At the bottom of the equipment, nozzles are arranged through which the cement suspension is injected perpendicular to the axis of the drilling equipment. Cement suspension is injected under a pressure of 400 bar.

There are four system of jet grouting. The most appropriate choice depends on the type of soil, the type of application, and the physical characteristics of the jet grouting body needed for a particular application.

The diameter of jet grouting column depends on technology and soil type.

When the jet grouting is performed by a single fluid system, columns of 0.6 to 1.2 m in diameter are formed. The process can be successfully applied in gravels, sands, and silts, while in clays it is less efficient.

The double fluid system performing achieves diameters up to 1 m in dense soils and up to 1.8 m in loose soils.

In the triple fluid system, higher quality columns of larger diameter (0.9 – 1.5 m) can be achieved. A triple fluid system is most efficient in cohesive soil. When super injection is performed, columns of 3 to 5 m in diameter can be achieved.

In order to verify the design parameters, a test field should be performed in which the jet grouting will be carried out by a procedure foreseen within the design documentation.

The basic advantage of jet grouting is that it can be used to reinforce all kinds of ground soils (gravel, sand, silt, clay) with environmentally friendly water-cement injection materials. The injection can start at almost any depth and be completed at any level below the ground surface, depending on the need for soil strengthening.

The injection can be performed vertically, horizontally and inclined relative to the surface of the ground.

The basic disadvantage present in all jet injection systems is the requirement to ensure smooth fluid communication (flow) from the injecting position to the surface. If communication is prevented, the pore pressure in the ground increases to the injection pressure (300 to 500 bar), this can cause hydraulic fracture of the soil. The consequences are lateral displacement and ground elevation.

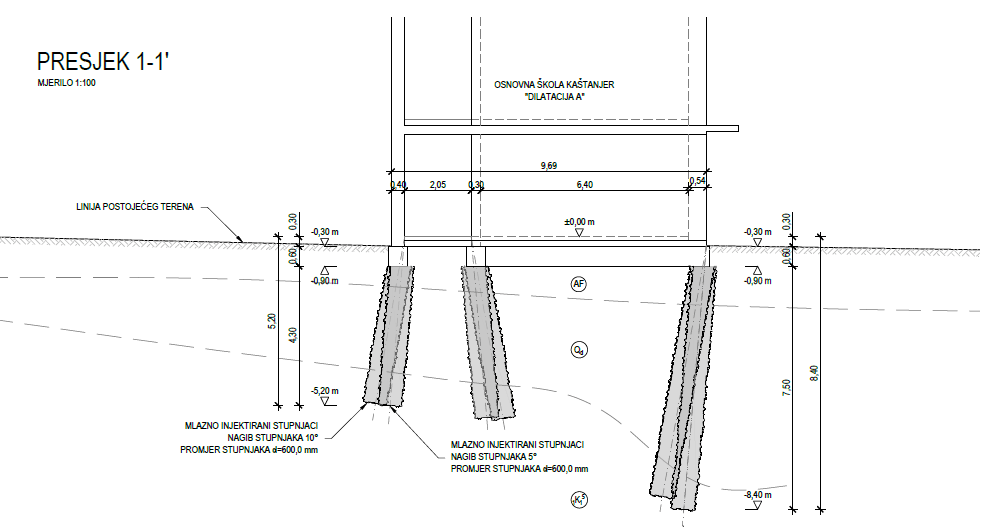

One of our project in which we have foreseen the foundation remediation with jet grouting is the elementary school “Kaštanjer” in Pula. The remediation of the foundation structure was performed by the single fluid system. Columns were performed in pair with a diameter 600,00 mm. The columns were conducted to a depth of at least 1.0 m within the bedrock.

We have also foreseen foundation remediation with jet grouting for the revitalization of the former industrial complex “Rikard Benčić”.

https://www.youtube.com/watch?v=GsoGE-ho9aM&feature=youtu.be