Execution of reinforced concrete diaphragms

A reinforced concrete diaphragm is a reinforced concrete structure used for open pit protection. The construction has the task to protect the stability of the vertical excavation of the open pit, to prevent displacements that could cause damage to neighboring buildings and installations, and to prevent the penetration of groundwater into the open pit.

Reinforced concrete diaphragms are built when it is necessary to construct deep open pits in urban areas where works are conducted in the immediate vicinity of existing buildings, in a cramped construction site and in the case of high groundwater levels.

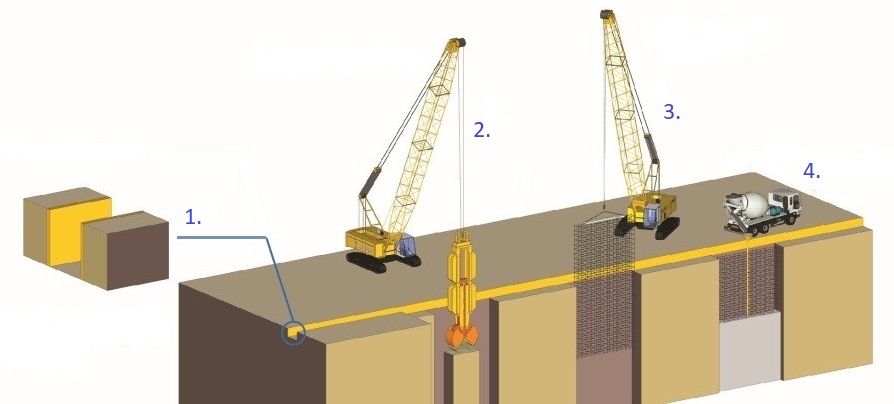

Procedure for the execution of reinforced concrete diaphragms:

The stages of execution of reinforced concrete diaphragms include:

- Construction of guid wall

- Excavation for reinforced concrete diaphragm

- Installing the armature basket

- Concreting of reinforced concrete diaphragm

Construction of guid wall

Guid wall is used for storing drilling fluid during drainage and supply. The drilling fluid is a suspension of bentonite clay in water and it fills the excavated space in the soil to prevent the flow and soil erosion in the excavation (the principle of hydrostatic pressure). The guid wall is usually made in one-sided formwork by constructing two concrete walls in the soil with a height of h = 0.80 m – 1.0 m and a variable width that depends on the width of the diaphragm.

Reinforced concrete diaphragm excavation

The excavation of reinforced concrete diaphragm is conducted with a mechanical grab. The grab allows deeper excavations of 30 m and a width of 0.80 m. The reinforced concrete diaphragm is made in stages, with the odd-numbered panels being executed first, and after them the even-numbered panels. When excavating, the panel is immediately filled with drilling fluid to maintain its shape.

Odd-numbered panels are fitted with tubes of the same diameter as the panel on each side, to enable the correct shaping of the panels.

Diaphragm reinforcement and concreting

In order for the reinforced concrete diaphragm to take over the bending moments, reinforcement must be installed in the concrete, and this is placed in the excavation by a crane.

Concreting is performed using the contractor procedure. Concrete is installed through a funnel at the top of the tube of length approximately equal to the length of the excavation. Because the infill is heavier than the drilling fluid, it displaces the drilling fluid to the surface during concreting. Due to its density, the filling spills conically in space.

When the concreting of the odd-numbered panels is completed and the concrete hardens, the installed tubes are removed. After that, the excavation of steam panels begins. The steam panels adhere completely to the already finished element, and the impermeability and continuity of the reinforced concrete diaphragm is achieved.

Since the drilling fluid is squeezed out of the excavation during concreting, a 0.5 m to 0.8 m thick layer of filling of poor characteristics appears at the top of the filled excavation, which needs to be removed. Upon completion of all the works, the guid wall is removed. After construction, the diaphragm panels are connected to the capping beam and the excavation of the open pit begins.

Protection of reinforce concrete diaphragms

In case of large depths, reinforced concrete diaphragms cannot independently protect the stability of the excavation—it must be additionally protected by the construction of geotechnical anchors, prop loads or tensions. When there is no possibility of such protection, the open pit can be protected by the execution of horizontal structural elements (reinforced concrete slabs) of the building or by applying the top-down method of construction.

Conclusion

Since reinforced concrete diaphragms can be an integral structural part of a future building, they represent a very effective way of open pit protection in urban areas with limited space. Also, since reinforced concrete diaphragms represent a continuous reinforced concrete wall in the foundation soil, they are very effective for open pit sealing in locations with high groundwater levels.

*References:

Prof. dr. Ervin Nonveiller, Mehanika tla i temeljenje građevina, dipl.ing.građ, Zagreb, 1979.

Prof. dr. Mustafa Selimović, Mehanika tla i temeljenje, dipl.ing.građ, Mostar, 2000.

Danijel Kišiček, Primjer analize i izrade dijafragme kod zaštite građevinske jame, diplomski rad, Varaždin, 2011.