Protective mesh

Rockfall is one of the most dangerous types of instability in the rock mass. Since this phenomenon is common in mountainous areas, suitable geotechnical interventions for existing infrastructure protection (roads, railways, etc.) are needed. One of the most favourable methods of rock slope protection in such cases is the application of a protective mesh.

Basic protective mesh features

Rock slope protection often includes the installation of galvanized double twisted wire mesh type 8×10, and less frequently 6×8. The 8×10 protective mesh type has the following technical features:

- Mesh type: hexagonal

- Mesh size: X x Y = 8.0 x 10.0 cm

- Min. steel wire diameter: d = 2.70 mm

- Wire tensile strength: 350-550 N / mm 2

- Wire corrosion protection composition: 95% Zn, 5% Al

- Wire and rope corrosion protection: galvanization – class A according to HRN EN 10244-2 (minimum 245 g / m2)

Photo 1. Detail of protective mesh

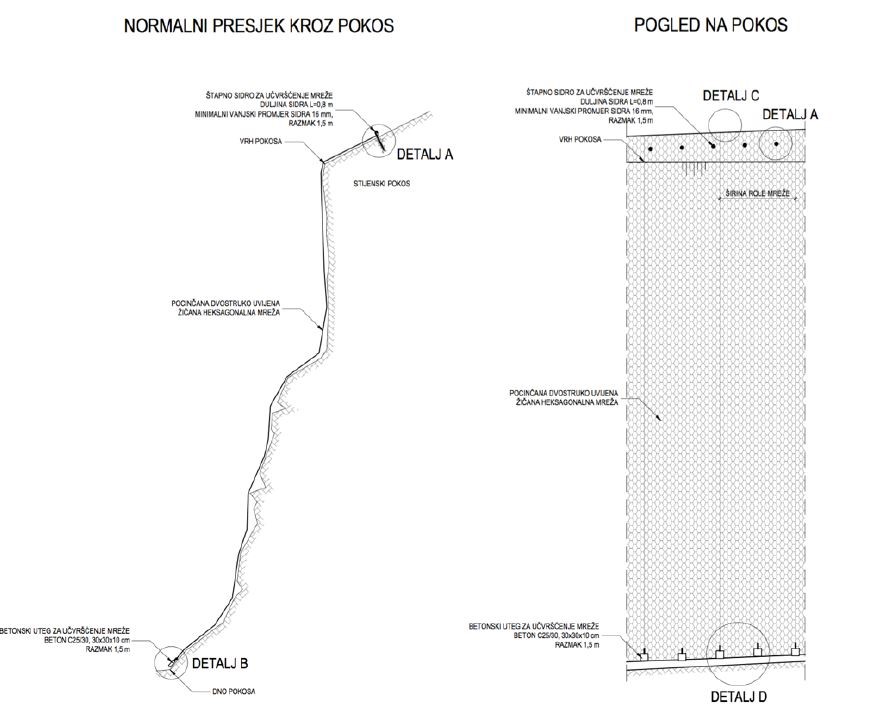

In order to accomplish the function of stabilization of smaller rock blocks, good mesh adhesion with the substrate is required with a maximum deviation in length of 5.0 cm to 1.0 m. This type of slope protection includes mesh installation on the face of the slope and in the area above the slope within 1.50 meters.

Photo 2. Protective mesh on the cut of the road

How to install a protective mesh?

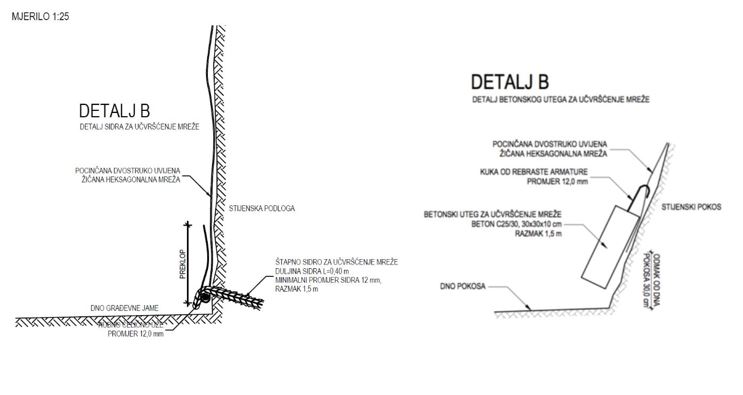

The mesh is installed on the surface of the slope which needs to be cleaned of vegetation and unstable blocks. It is also necessary to clean up and regulate 1.5m of hill-side above the edge of the slope. The anchors at the top of the slope must be executed first. Boreholes 25.0 mm in diameter are performed using a hand drill. The anchors made of a ribbed reinforcement B500B (16.0 mm in diameter, with a hook end) must be installed in the borehole. The anchors need to be a minimum length of 80 cm (longer if necessary, depending on the quality of the rock mass). The hooks at the end of the anchor are turned from the edge of the slope so that they can accept the steel rope that is connected with the protective mesh. The anchors are installed at distances of 1.50 m. It is necessary to ensure that the surface of the slope is cleared, so the mesh can be set onto the substrate. Unfolding can be performed from the foot of the slope up or unwinding with a crown slope downwards.

Photo 3. Protective mesh-performances

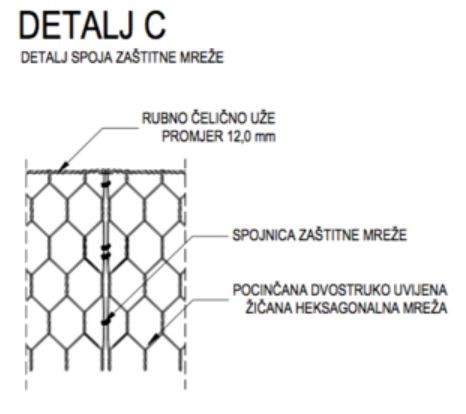

After mesh installation, it is necessary to interlock the steel wire (diameter of 12.0 mm) below the installed anchors at the top of the slope (all along the slope where the mesh is installed) and make the transition over the steel wire rope. Steel wire rope is installed to secure the mesh to the entire width of the panel, not just on the anchor position. The assembled mesh panels are connected with galvanized rings, after the 4-5 panels are installed.

Photo 4. Panel connection detail

There are two common ways to secure a protective mesh.

One way is to strengthen the mesh with concrete weights on its bottom. The weights are made of concrete with compressive strength class C 25/30, dimensions 30x30x10 cm. The reinforcing steel rod B500B with diameter Φ = 12.0 mm is anchored in the concrete weight. The steel rod is shaped like a hook which enables acceptance of the concrete weight and fixation of the mesh at the bottom of the slope.

Another way is to use a short anchor 40 cm in length, with a diameter of Φ = 12.0 mm which accepts and secures the mesh at the bottom of the slope.

Slika 5. Details strengthen mesh with concrete weights and anchors

Photo 6. Protective mesh fixed with concrete weights

Conclusion

Slope protection with protective mesh is one of the fastest and best ways for slope protection. The price for a protected area ranges from 40 to 50 kunas per m2. Because of its simplicity, it can be combined with other protection measures such as anchors (before or after the mesh installation), but more about that in another blog…