Open pits protection design – the Glamping camp at Fužine

The construction of a glamping camp is planned in the town of Fužine, along the southwestern shore of Lake Bajer. The camp will have 15 accommodation units, a central building, and a garage. The construction will take place on a newly formed building plot with a unique area of about 12,000 m2.

Planned works

Project plans include the building of 15 glamping accommodation units, a central building with a reception, wellness, swimming pool, bar, and conference room, and an underground garage with 39 parking spaces. The main project for the glamping camp was designed by the AO16 architects from Rijeka.

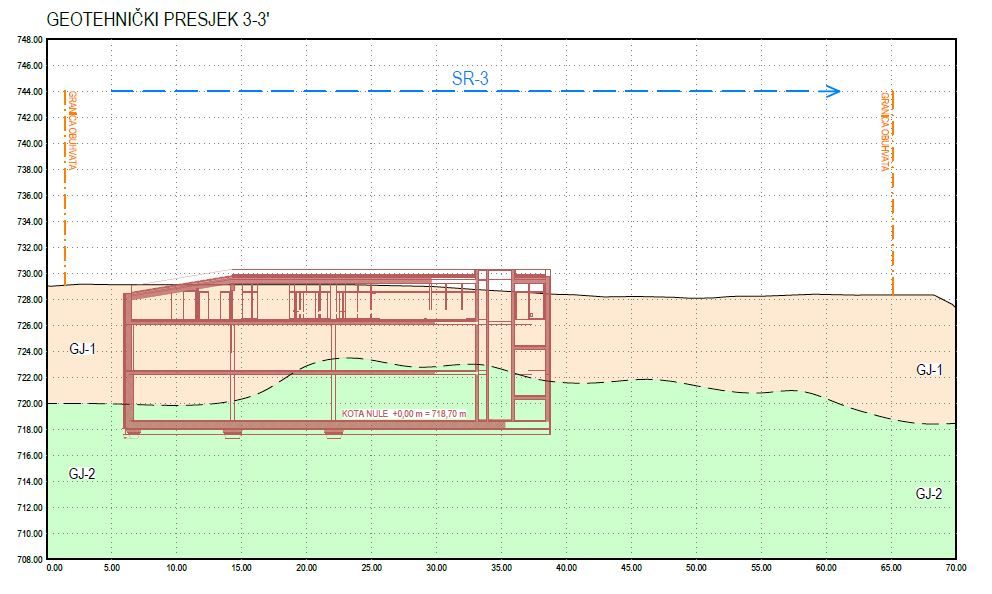

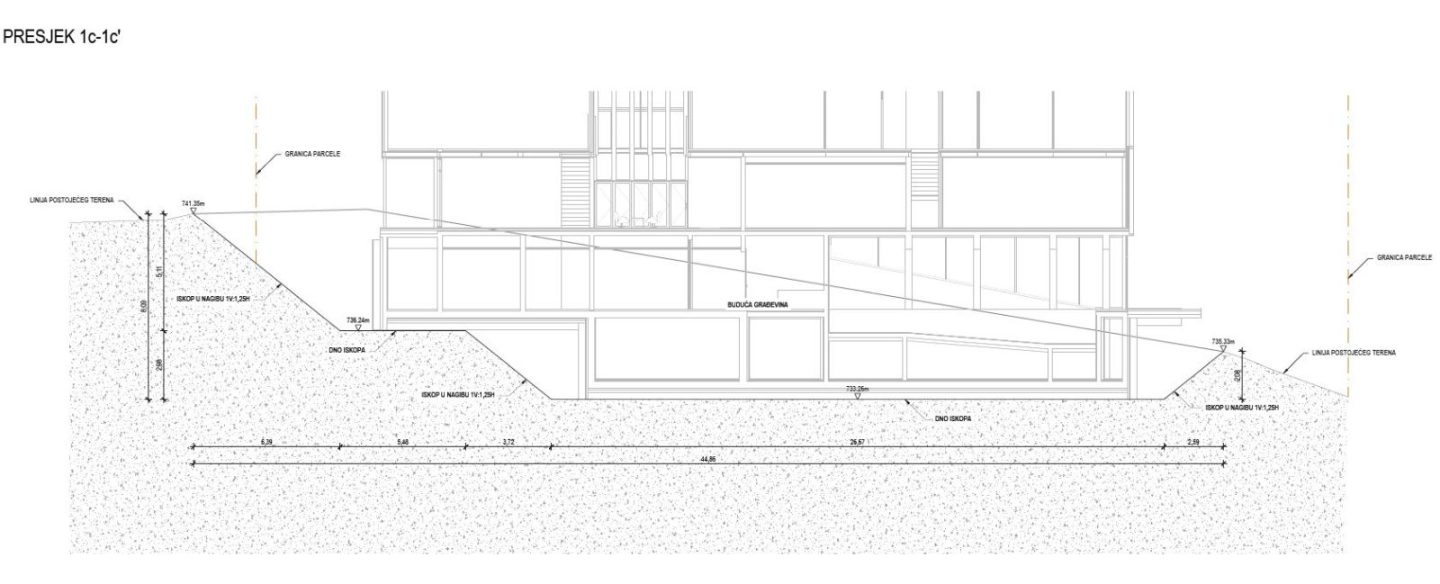

In order to construct some of the listed facilities, the existing terrain needs to be excavated to a depth of approx. 15.0 m (for the garage), 8.0 m (for the central building) and 2.60 m (for the buried accommodation units) and temporary open pits need to be provided.

Geotechnical investigation and testing

In order to prepare the temporary open pit protection design, engineering-geological and geotechnical investigation and testing were carried out. The works included engineering-geological and geotechnical prospecting of the location, exploratory drilling with coring, determination of drill cores, standard penetration testing (SPT), geophysical testing, laboratory testing of samples and processing the data from earlier investigations.

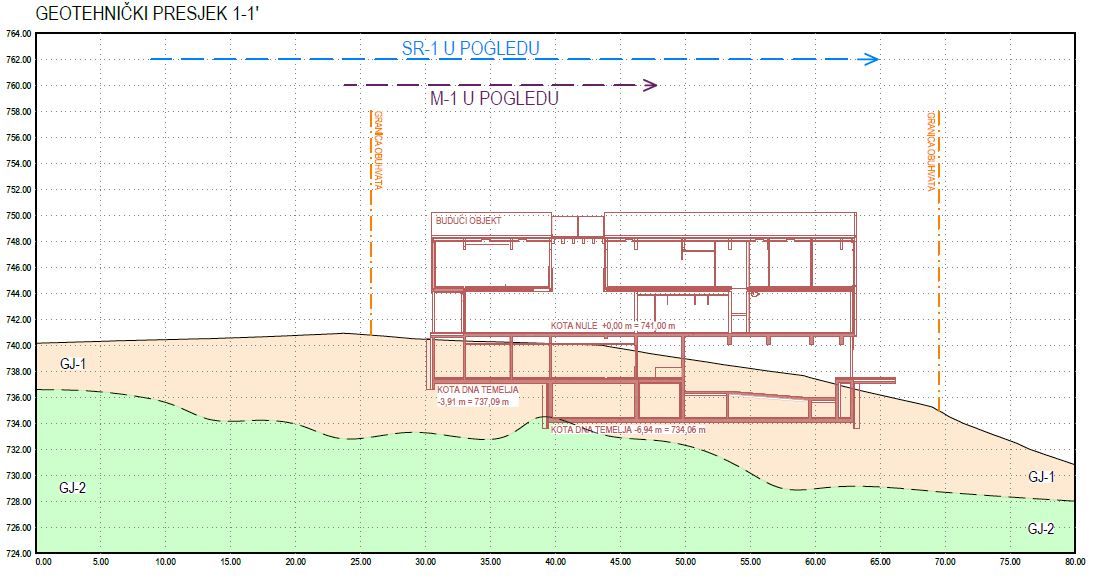

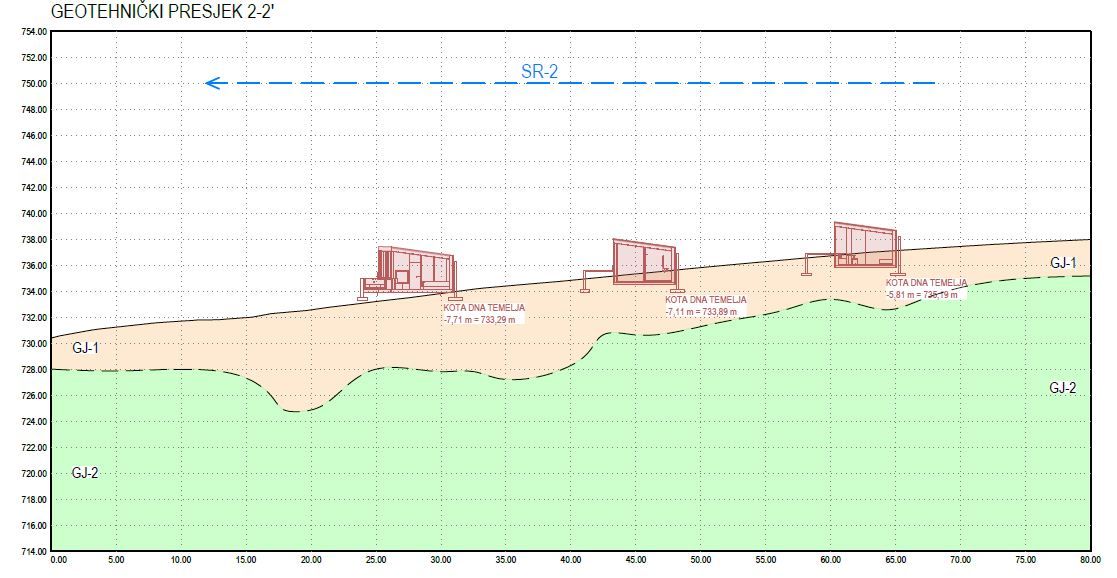

The investigation and testing concluded that the location in question is made up of deposits of cover (diluvium/eluvium) that extend above the bedrock made of clastite (medium weathered rock mass).

Open pits protection

With regards to the spatial limitations and the geometric and geological characteristics of the terrain at the location of the planned structures (garage, central building, buried accommodation units), it was determined that the open pit for the central building (depth 8.0 m) and the open pit for the buried accommodation units (depth 2.60 m) can be excavated in a stable geometry within the cover (1V:1H, 1V:1.25H) without additional protection measures. The open pit for the garage (depth 15.0 m) had to be built within the bedrock and cover with additional protection.

The open pit protection for the garage is divided into a total of five zones, with the boundaries of the zones defined by the geometry of the excavation, depending on the spatial limitations. In general, with regard to the size of the construction project, excavation protection measures are provided for the parts of the pit where it is impossible to excavate in a stable geometry due to spatial limitations (excavation at a slope of 2V:1H in the rock mass and excavation at a slope of 1V:1H and 1V:1.50H in the cover).

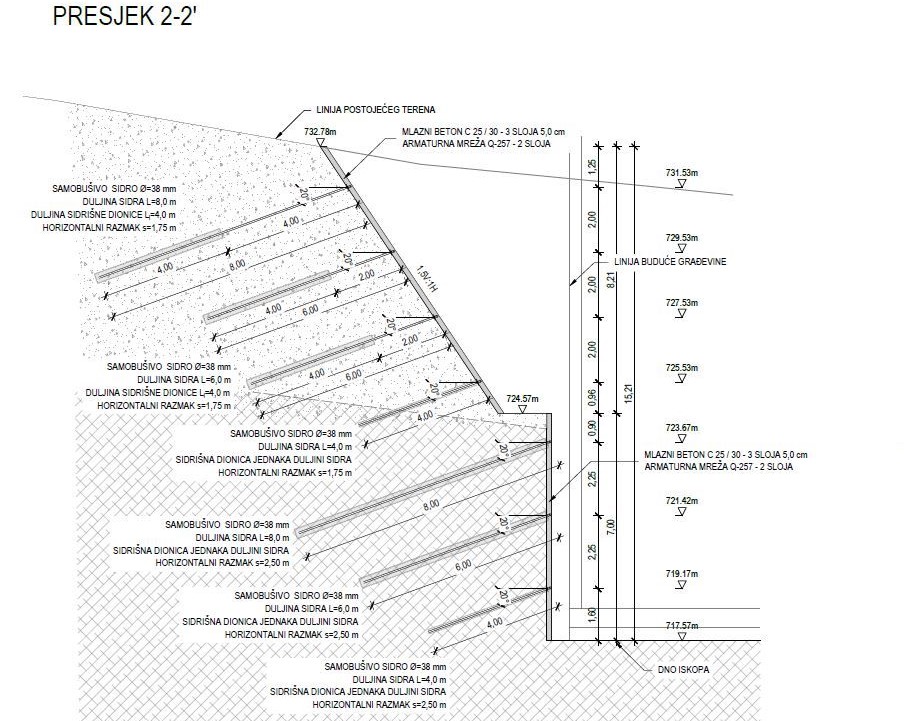

For the excavation within the cover, where spatial limitations make the excavation in a stable geometry impossible, a steeper excavation (excavation at slopes of 1.50V:1H and 3V:1H) with nailed soil is planned. Nailed soil is made by installing self-drilling anchors with a diameter of 38.0 mm, lengths of 4.0, 6.0 and 8.0 m, with a load capacity of 35.0 tons in a general grid of 2.0 x 1.75 m. Along with the self-drilling anchors, shotcrete will be installed in three layers 5.0 cm thick, with two layers of reinforcing mesh Q-257 between them.

For the excavation within the clastite rock mass, the vertical excavation will be protected by installing self-drilling anchors with a diameter of 38.0 mm, lengths of 4.0, 6.0 and 8.0 m, load capacity of 35.0 tons in a general grid of 2.25 x 2, 50 m, combined with shotcrete which will be installed in three layers 5.0 cm thick, with two layers of reinforcing mesh Q-257 between them.

Conclusion

During the excavation and protection of the open pit for the garage, continuous geotechnical monitoring, engineering geological mapping, and monitoring of the movement of the open pit need to be carried out. The measuring equipment that will be used for the monitoring consists of geodetic measuring points (5 points are planned along the open pit).

The open pit protection concept that was chosen—nailed soil within the cover and anchoring of the rock mass in a larger grid—ensures global stability of the excavation of a total height of up to 15.0 m and a significant reduction in the total amount of excavated material expected due to the large area of the future garage and the sloping terrain on the location.

Read more: Open pit protection designs