Mixed in place method

One of the soil mixing methods is Mixed in place method (MIP) that has been developed and patented by BAUER company.

Description of the method

Mixed in place (MIP) refers to mixing the existing soil in situ with a binding agent. A triple auger is used to break up the soil. During this process, the existing pores within the soil structure are filled with the binder slurry. This process results in the formation of “concrete” in which the soil is being used as aggregate.

The result of this process is a strengthened body of soil, the shape of which is defined by the geometry of the augers.

Construction of an MIP trench is carried out by drilling a triple continuous flight auger to the required depth. During drilling and withdrawal of the augers, the soil structure is destroyed, the soil is thoroughly mixed and binder slurry is introduced through the hollow stems of the augers.

During the subsequent homogenization process, the direction of rotation of the individual augers is varied so that circular material flow is produced in the trench. This vertical material flow is only made possible through the use of augers with continuous flights, which ensures the homogeneity of the soil binder and thus of the finished wall.

Picture 1. Mixed in place method

Applications

The MIP method is particularly suitable in non-cohesive soils for the construction of cut-off walls as groundwater or pollution control, for remediation of embankments and dams or open pit protection. Another area of application is the construction of foundations for buildings.

Construction sequence

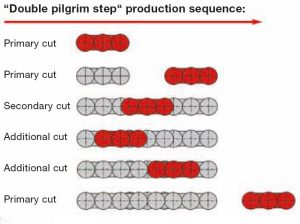

To ensure that a solid watertight wall is produced, construction of the MIP walls is carried out in bites by adopting the so-called ‘hit-and-miss’ construction sequence („Double Pilgrim Step“).

This method is characterized by additional processing of the overlapping areas comprising primary and secondary panels. This guarantees the triple auger penetrates and processes each wall element at least twice.

The drilling rig is set up over the position. It then drills the triple flight auger assembly mounted at the front end of the rig into the ground whilst slurry is injected continuously through the central starter auger section. By reaching the specified final depth, mixing and homogenization of the soil material is carried out by vertical (upward and downward) and rotational movements of the auger unit.

Picture 2. Construction sequence „Double Pilgrim Step“

Wall properties – types of slurry

The mechanical properties of MIP walls depend essentially on the physical properties of the in situ soil material, which is used as aggregate, and on the materials used in the slurries. Mix designs are mainly cement based or consist of a blend of cement and bentonite. The compressive strength achievable in structural MIP walls is 5 to 20 N/mm2. Cut – off walls generally produce a compressive strength of up to 1 N/mm2.

Equipment

Mixed in place equipment is composed of auger drive unit, triple augers and cement slurry mixing and pumping plant.

Mixed in place equipment is developed specifically for use in the granular, slightly cohesive soils. The entire hydraulic power for the rotary drives of the attached triple augers is provided by the hydraulic system of the base carrier.

Picture 3. Mixed in place equipment

Quality assurance

Suitability tests are conducted before beginning the installation in order to determine the composition of the binder slurry as well as the quantities required for installation. Binder slurry composition and quantity of it are determined on the basis of soil and groundwater characteristics from the site.

In the laboratory, different binder recipes are mixed with soil probes taken on-site and characteristics of the hardened Mixed in place material are tested.

The key production parameters, such as drilling depth, slurry flow rate, oil pressures and the number of drilling tool revolutions as well as the verticality of the triple auger are continuously displayed and recorded for the rig operator during execution. Reference samples are additionally taken at regular intervals from the fresh trench. They are used to monitor the specified properties of the fresh suspension and of the hardened MIP compound.

Advantages of the mixed in place method

By using mixed in place method soil structures are homogenized. Using the in-situ soil as building material (aggregate) conserves resources. The low-vibration construction technique using rotary drilling reduces the strain on sensitive neighboring buildings and previously damaged dams and dikes. The mix design can be changed on the construction site at any time and the construction period is short.

Summary

The MIP method is particularly suitable in non-cohesive soils for the construction of cut-off walls as groundwater or pollution control, for remediation of embankments and dams or open pit protection. Another area of application is the construction of foundations for buildings.

Mixed in place (MIP) refers to mixing the existing soil in situ with a binding agent. A triple auger is used to break up the soil. During this process, the existing pores within the soil structure are filled with the binder slurry. This process results in the formation of “concrete” in which the soil is being used as aggregate.

Reinforcing elements can be installed in it for structural strengthening (universal steel beams or sheet piles).

*References:

Girsch E., Mixed-in-place – A technique for the construction of subterranean walls and foundations, RMZ – Materials and Geoenviroment, Vol. 50, No. 1, pp. 129-132, 2003.

Bauer, Mixed-in-Place