Measuring equipment for displacement monitoring

(Inclinometers, Geodetic Points and Clinometers)

The term deformation refers to all the changes that occur on infrastructure facilities or structures, in their surroundings during construction or use, as well as changes that occur after the completion of structure construction or on slopes — landslides. Geometric changes that occur on structures can be related to the movement of the entire structure, or a part of it, with tilting, bending, stretching and the resulting tension in the structure. All this is the result of various factors, or forces, which constantly, periodically, regularly or irregularly act on the structure. Possible consequences can be prevented by detailed geotechnical and geodetic investigations, which include actions to monitor vertical displacements, slopes and cracks after the movement, settlement, cracking or tilting of the structure has been established.

The measurement of deformations and displacements is carried out to ensure against sudden and unpredictable occurrences on structures, to check the stability and settlement of embankments, retaining structures, foundations and slopes. It is essential that all events and conditions that could affect the safety of the facilities and their later use are recorded on time. Therefore, the role of monitoring is crucial. Monitoring is the basis for introducing a displacement and deformation control system and deciding on the necessary measures depending on the condition of the observed structure or landslide. Monitoring is the monitoring of the structure, integrated into a unique system with a system for reporting and visual representation of construction or geotechnical structures. Monitoring is carried out for research and warning in real-time. Furthermore, monitoring after the execution of any remediation is carried out as a check of the success of the works executed.

When choosing measuring equipment, it is advisable to choose direct methods and equipment with measurement results that directly refer to the behavior of the structure, the surrounding soil or the slope. The methods used to determine displacement are remote observations, photogrammetric methods, geodetic methods and geotechnical methods.

Geodetic and geotechnical methods will be described in more detail below.

Geodetic displacement observations

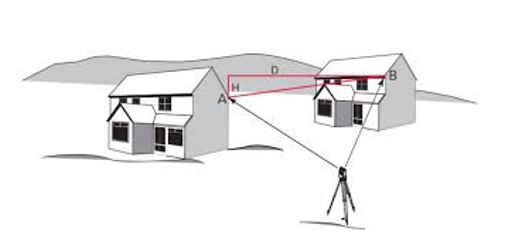

The geodetic method of measuring deformations is based on the application of precise geodetic instruments to determine the displacement of individual control points, arranged in a convenient way. The measurement determines the relative change in the position of these reference points in the spatial coordinate system. More specifically, they are used to determine the relative or absolute coordinates of individual points, which include classic geodetic instruments and instruments for determining coordinates via satellite, such as GPS (Global Positioning System).

Observations with the application of geodetic measurement methods are carried out before, during and after construction. Geodetic observations make it possible to determine vertical and horizontal displacements, and thus the direction and speed of displacement. The magnitudes and directions of the displacement of points can be calculated from the difference of the measured coordinates in two consecutive measurements. Some of the instruments used during geodetic observation of displacement are:

– leveler;

– theodolite;

– total station; and

– global navigation satellite system (GNSS).

Geotechnical displacement observations

Geotechnical displacement observations are most often based on the use of measuring devices such as inclinometers and clinometers, which is explained in more detail below.

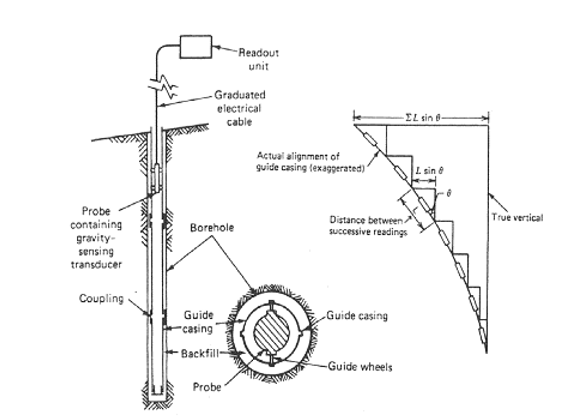

Inclinometers are used to measure the change in inclination of vertical casing boreholes or pipes embedded in retaining structures. On the example of a landslide, this determines the depth of the slide as well as the direction, size and speed of movement between individual measurements. Inclinometers can be divided into two types: test and built-in inclinometers.

In the case of test inclinometers, pipes with guides are installed in the boreholes. A measuring probe with wheels that are inserted into the guide measures the incline between two measuring points where the wheels stop, at certain intervals. Using a probe with built-in sensors, it is possible to measure the incline in one or two mutually perpendicular directions. The accuracy of test inclinometers in field conditions reaches ± 0.1 mm/m.

With built-in inclinometers, the probes are equipped with sensors and are installed at depths where, for example, sliding is expected. Results from the inclinometer can be recorded periodically or continuously and sent to a data acquisition and processing system.

A clinometer, also known as a clinometer compass and an electronic clinometer, is commonly used to measure a horizontal angle, relative angle and inclination. The measurement is based on the measurement of the angles of rotation built into the structure of special supports, which are installed by a special drilling and injection process.

The number increases when the axis in the clinometer base is turned in one direction and decreases when the direction of rotation changes. Counting is related to the initial position of the clinometer. When the clinometer is initialized, its counter is set to 0. By calculating the angle of rotation, position and velocity can be easily measured. The difference of the obtained result between the two measurements is the turn of the support expressed in mm/m.

In order to better identify and later reduce or eliminate potential risks for structures and persons, it is necessary to define the purpose of the measurement, the measured quantities and the measurement equipment. Geodetic and geotechnical measurements are indispensable, especially during construction and the remediation of damaged structures. In order to avoid cracking, sliding or collapsing of the structure, it is necessary to monitor displacements and deformations. The development of measurement and control technology enables us to measure and monitor displacements and deformations with an accuracy better than 1 mm.