What are self drilling anchors?

Self drilling anchors

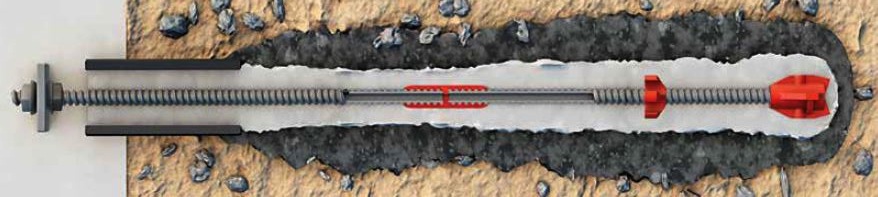

Self drilling anchors are special type of rod anchors. Self-drilling anchor consists of a sacrificial drill bit, hollow steel bar of the appropriate outer and inner diameter and coupling nuts.

The anchor body is made of a hollow steel tube with an outer round thread. Steel tube has the sacrificial drill bit at one end and the corresponding nut with a steel end plate.

Self drilling anchors are used in a way that hollow steel bar (rod) has a corresponding sacrificial drill bit on its top instead of a classic drill bit.

Centralisers guarantee a consistent grout cover around the hollow steel bar and that the bar remains in the center of the drilled hole.

Construction of self drilling anchor

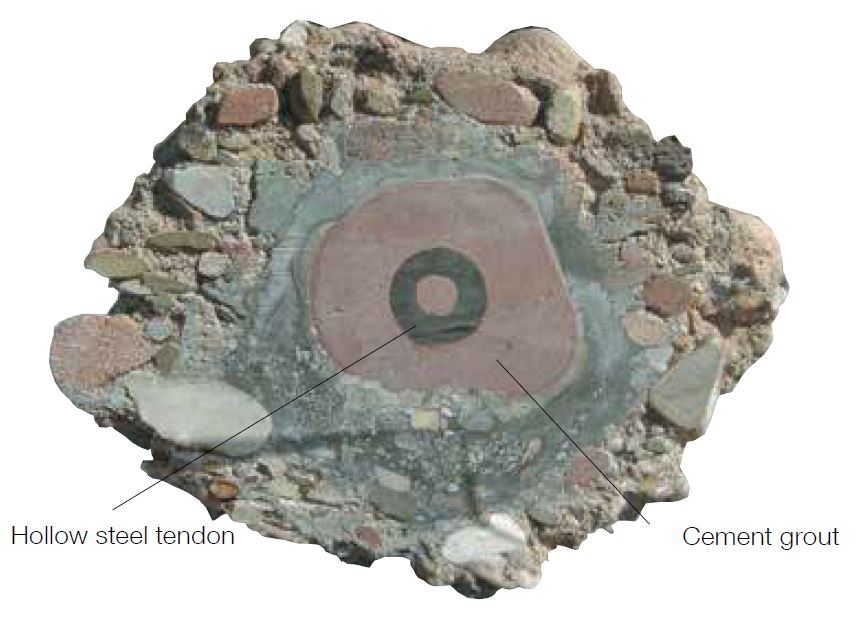

Anchor hollow steel bars are produced in sections with standard lengths of 2.0, 3.0 or 4.0 m. The standard outer diameter of the hollow steel bars ranges from 30.0 mm to 127.0 mm.

If necessary, hollow steel bars are continued with coupling nuts. Different types of sacrificial drill bits are used depending on the type of soil or rock mass. A hollow steel bar is better than a solid bar with the same cross-sectional area because of its better structural behavior in terms of buckling, circumference (bond area) and bending stiffness. The result is a higher buckling and flexural stability for the same amount of steel (cost of material).

Hollow steel bars

In the case of special durability requirements and more aggressive soils, hollow steel bars could be corrosion protected by hot-dip galvanizing or its material could be stainless steel.

Self drilling anchor cross section

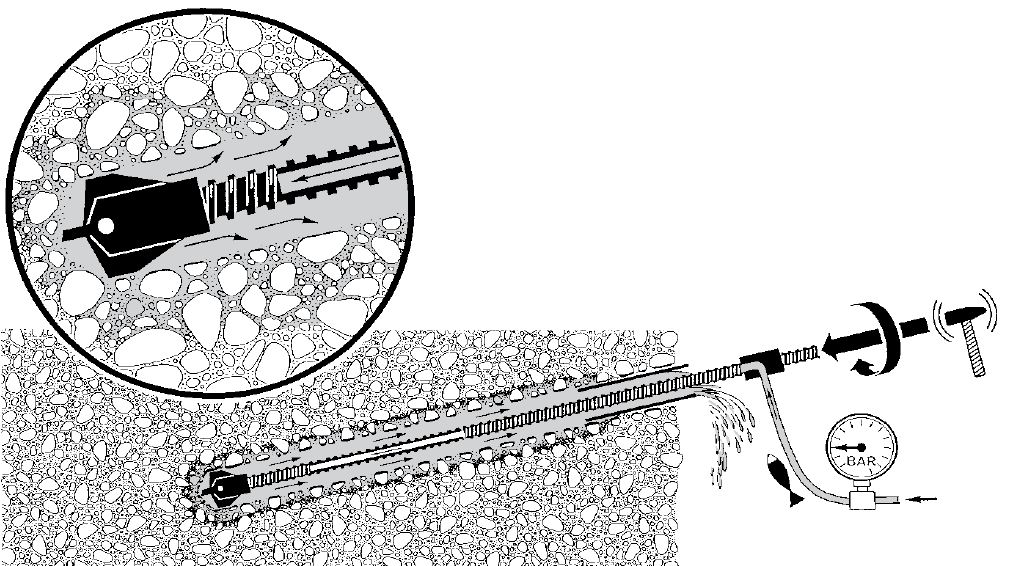

Installation of self drilling anchors

The hollow steel bar is driven to the required depth by means of rotary percussive drilling. Injection is carried out through hollow steel bar. Injection mixture flows through the holes at the sacrificial drill bit and automatically stabilizes the drilled hole. Injection ends when the mixture begins to exit from drilled hole. The cement grout is most often used for injection of self-drilling anchor. The usual water-cement ratio ranges from 0,40 to 0,50.

Anchor grouting

Installation of self drilling anchors

Range of applications and advantages of self drilling anchors

The basic application of self drilling anchors is installation under the conditions of the soil/rock with the risk of drill hole collapse due to pulling out of drill bit as in the classical anchor installation process.

Self drilling anchors can be installed in length greater than classic rod anchors (joining of a hollow steel bar with coupling nuts).

Range of applications:

• micropiles for foundation underpinning (anchors with larger diameter)

• anchors against uplift

• anchors for protection of rock slopes and building pits

• anchors for stabilization of soil slopes (soil nailing)

• anchors for stabilization of embankments

• anchors for protection of retaining structures

• drains (drainage of water)

Installation cost

Installation of self drilling anchors depending on the diameter of anchors used, installation conditions, material quality and anti-corrosion protection ranges from 250,0 to 350,0 kn per m’ of an anchor.