Offshore exploratory drilling

Exploration for construction of marine structures

Offshore exploratory drilling includes a combination of drilling, sampling, in situ testing, as well as laboratory tests on soil and rock samples. Marine structures belong to a group of extremely complex construction projects. It is very important to be familiar with underwater geological conditions in order to predict all the potential negative impacts on construction and to prevent them on time.

Structure foundations should be grounded in marine soil in order to provide mechanical stability and to withstand the sea currents, wind

Offshore exploratory drilling can be performed from land if the new structure is planned along the existing coast. But in most cases, it also includes the use of a vessel or pontoon for drilling equipment transport and drilling performance at the seabed.

The differences between offshore and onshore exploratory drilling:

- Offshore exploration and investigation works are more expensive.

- Works are performed from the vessel or pontoon.

- More staff is needed (drillers, sailors, divers).

- Drillers must be highly skilled and experienced as they are exposed to a wider range of dangers than they would be drilling onshore.

- Weather conditions (wind, waves, tides

and currents) and the traffic of other vessels significantly affect the speed, safety and performance of the works. - It is necessary to consider the weather forecast, timetables for bigger vessels in proximity that could cause waves and perform the works with increased caution for the whole time.

- It is necessary to perform grouting through the marine medium that serves as a drill rig and as protection against borehole cave-in.

- The waves and currents even during minimal vessel movement often cause a breakdown and damage to the drilling equipment and are a danger for persons nearby.

Two types of exploration boreholes are most often performed offshore:

Boreholes with coring and prospecting boreholes.

Offshore rotary core drilling

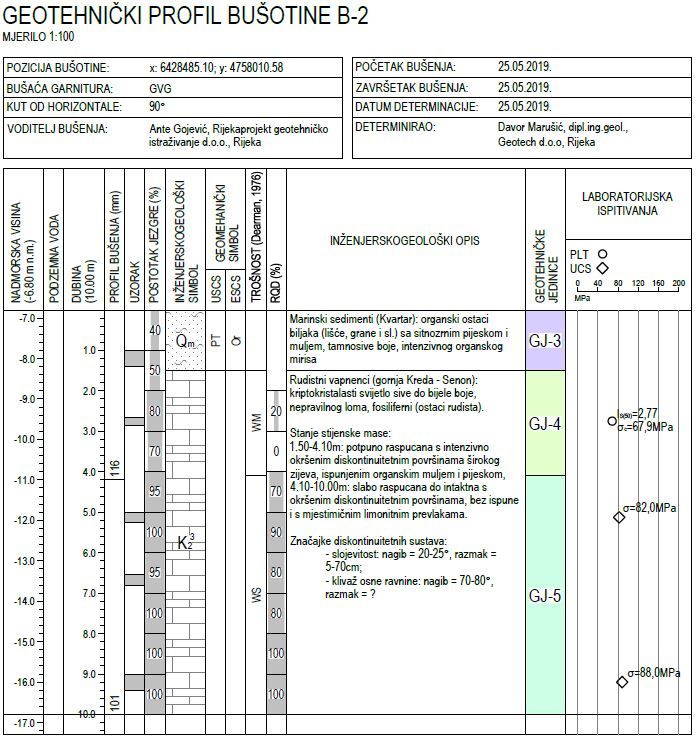

Offshore exploratory drilling is most often performed to the level of bedrock which is bedding with excellent features in terms of bearing capacity and deformability under the marinate sedimentation cover. Drilling with a minimum requirement of about 2.0 – 3.0 m penetration into bedrock is most common, and this depth may be greater depending on the type and size of the foreseen construction.

Drilling is performed by applying the rotary core drilling method using suitable drilling equipment. When drilling in compact rock it is necessary to use an industrial diamonds crown that is wear-resistant or a crown made of specially-treated steel for drilling through sediment and weathered rock.

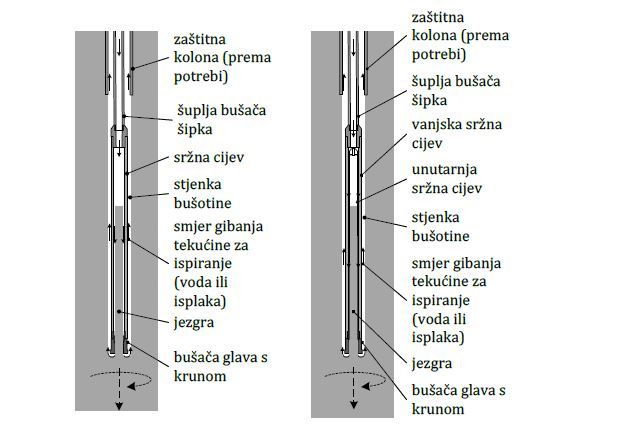

Unlike onshore drilling where the borehole can be protected against caving with a protective tube, in offshore drilling the casing is used to guide the drilling tool through the marine medium to the borehole entrance.

A double core tube tool has been developed in order to reduce the possible damage to the core (which is caused by the rotation of the core tube and by the passing cooling and rinsing water). The inner core tube is independent of the outside tube and supports the core. The inner core mostly releases friction from the outer tube rotation. The cooling and rinsing water passes between the outer and inner core tube, so the core is further protected and sample damage is minimized.

Prospection drilling

Offshore exploratory drilling includes the execution of penetrating (prospecting) boreholes without coring where the depth of penetration of the core tube through the sea sediment to the surface of the bedrock is measured. This is a fast and efficient way of obtaining data that is often used in combination with exploratory drilling with a core to obtain a more accurate geotechnical soil profile.

Vessel or pontoon

For the execution of offshore exploratory drilling, it is necessary to use a vessel or pontoon to transport the drilling equipment and perform offshore exploratory drilling. One of the most important factors affecting the total cost of the works is renting a vessel. The vessel is rented per day, and in

Jack-up pontoon

The jack-up pontoon is the optimal vessel when performing offshore exploratory drilling because of its excellent stabilization and low wave impact features. A jack-up pontoon is a vessel consisting of a vessel hull equipped with movable legs which allow the hull to be raised above the surface of the sea. The vessel hull allows for the transport of pontoons and all other equipment to the desired location. When the pontoon is positioned at the desired location, the hull is raised above the surface of the sea using its movable legs positioned firmly at the sea bottom. The movable legs must be designed to be able to penetrate the seabed and equipped with special supports. Such vessels may have their own propulsion systems or they are positioned using tugs or heavy lift ships.

Vessels in Croatia

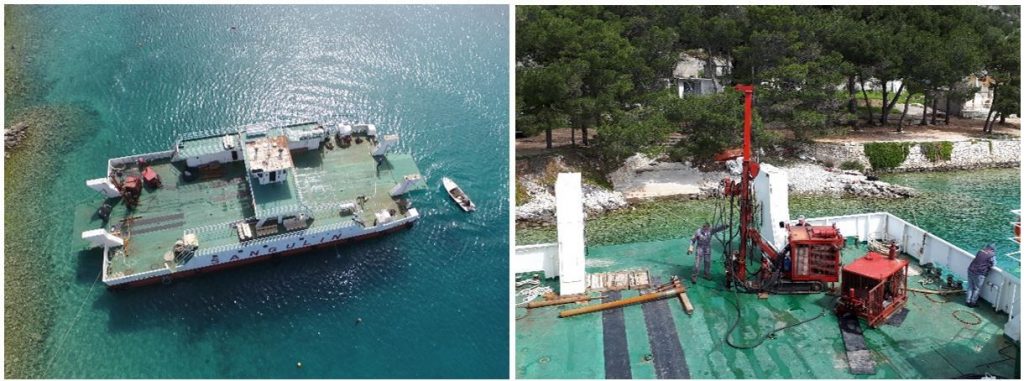

Multipurpose working vessels specially designed for offshore exploratory drilling are most commonly used in Croatia. They usually have two or four legs up to 10 m in length, so their use is limited to the relatively shallow sea. With two-legged pontoons, the legs penetrate the seabed and the other side of the pontoon is tied to the coast using ropes or it is anchored under the sea.

If the vessel does not have legs, a stern is used for anchoring or the vessel is docked to the coast using cross-linking mooring ropes and steel cables tightened to anchors using winches on submerged concrete blocks.

Offshore exploratory drilling, Dugovača bay, Zadar

For the reconstruction of the coastal area in Dugovača bay, stretching along the western outskirts of Draga, four exploratory boreholes with coring on the sea (12,0 m of total length with a minimum requirement for penetration into the bedrock of 2.5 m) were conducted. Five prospecting boreholes on the sea were conducted in order to determine the level of bedrock by penetrating through marine sediments.

The exploratory drilling was carried out from a vessel designed for exploratory drilling anchored in the stern on which drilling equipment was set. Exploratory boreholes were used to determine the geotechnical features of the location and soil foundation.

Offshore exploratory drilling – Korčula, Polačište

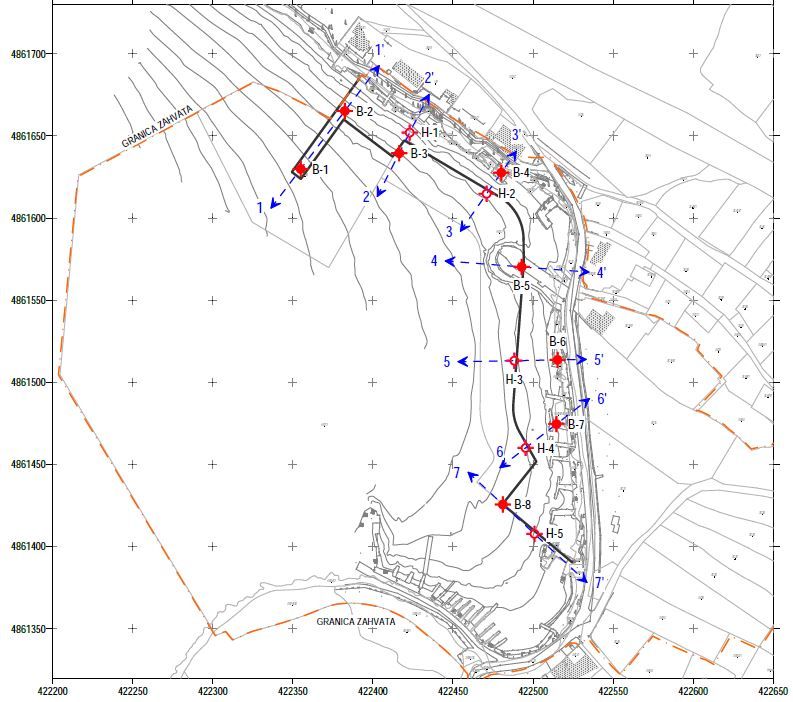

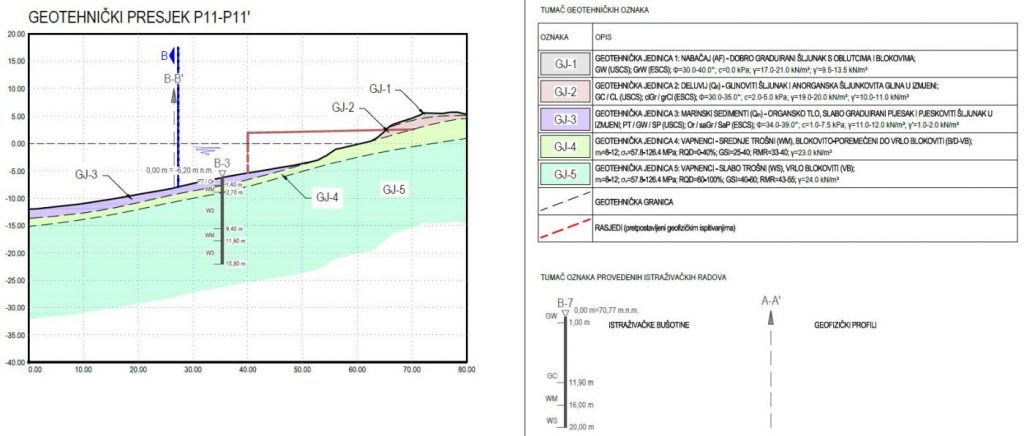

The project is located on the northern side of Korčula island, approximately 1.5 km west of the old town of Korčula, at Polačište. Within the scope of geotechnical exploration and investigation works for the construction of a port open to public traffic and for the purpose of geotechnical elaboration documentation, seven (7) offshore rotational boreholes were carried out, with individual lengths of 7.5 m to 15.8 m and a total length of 79.9 m. According to Client requests, the boreholes were conducted with greater depth within the bedrock than the usual minimum requirement of 3.0 m. The conducted exploration of the depth of marine sediments has concluded that the marine sediments are between 1.0 m to 1.8 m thick and that under the marine sediment cover there lies a medium to little weathering rock mass of limestone. The offshore exploratory drilling was carried out from a two-legged vessel, tied to the coast and the anchors using ropes and steel cables.

The geotechnical and engineering geological works were conducted from May to June 2019 and included the geotechnical prospecting and engineering geological mapping of the location, examination and determination of drilling cores, engineering geological maps, geotechnical location cross-sections and geotechnical profiles of boreholes.

Conclusion

Offshore exploratory drilling is extremely complex because of the unusual working and performance conditions and because of the costs, but engineers provide the best insight into the geotechnical soil profile, better than any other method. For this reason, it is necessary to perform offshore exploratory drilling to confirm the geophysical and other examinations and assess the potential problems of marine structures foundations and solve them in the best possible way.

Read more: Exploratory drilling