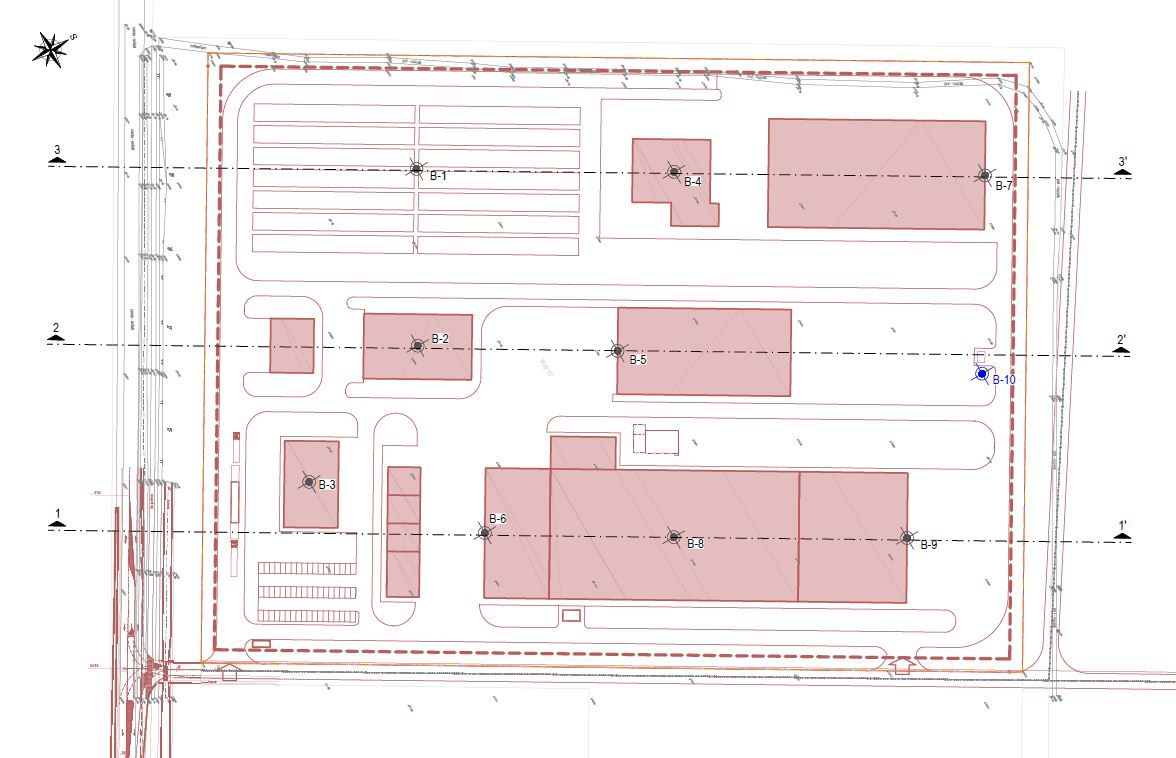

Foundation design for the construction of several facilities of a vegetable drying plant in Virovitica

To the northwest of Virovitica, in the village of Korija, the construction of a vegetable drying plant is planned. The plant will have a drying capacity of 410 kg of vegetables per hour.

For the construction, we made the main foundation design for the following facilities of the planned drying plant:

- production plant for preparing the vegetables for drying

- changing room for the workers

- cold storage for fresh vegetables

- storage for fresh vegetables

- boiler room

- woodchip storage

- administrative building

- water reservoir (underground water tank)

- substation

- hot water tank and

- technical building

Geotechnical investigation and testing

Before drafting the main foundation design for the listed facilities, the following geotechnical investigations and testing were carried out at the site:

– geological and geotechnical prospecting of the wider area

– exploratory rotary drilling

– engineering geological mapping of the terrain and determination of drill cores

– standard penetration test (SPT)

– laboratory tests

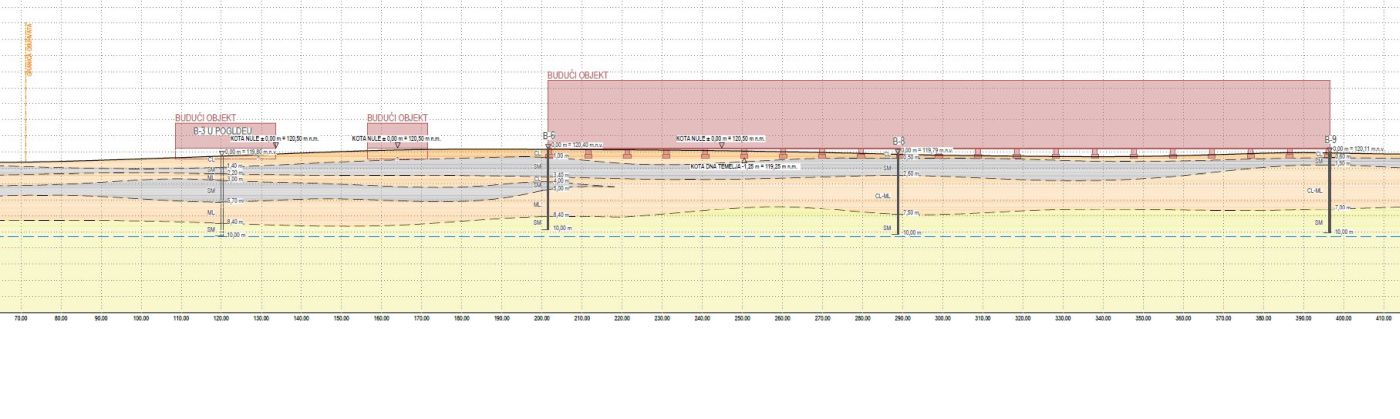

The investigations carried out found that the location is built up of Aeolian sands lying on Drava sands and gravels, and that soil improvements need to be carried out to prepare for the foundation works within the construction project.

Foundation of vegetable drying plant facilities

Taking into account the expected stress values for the foundation soil under the planned facilities, shallow foundations on foundation slabs, strips and spread footings were selected for all facilities.

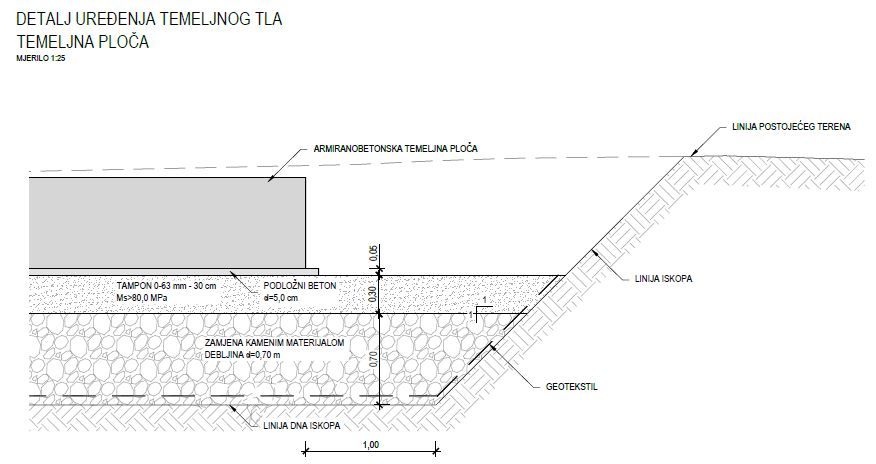

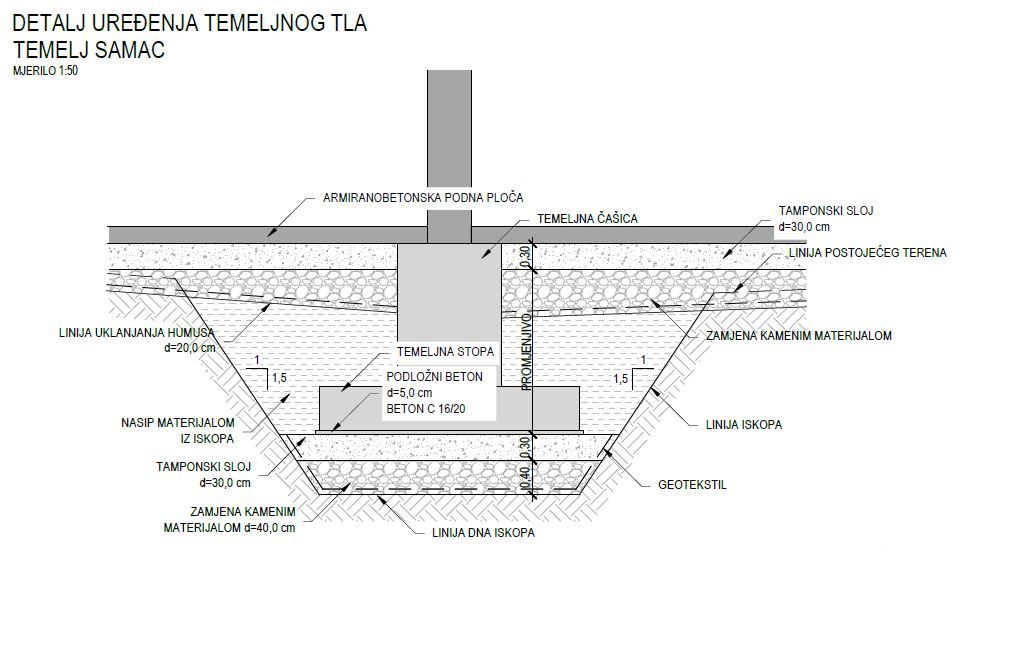

With the exclusion of the administrative building and the hot water tank, it was decided to carry out foundation soil improvements for the planned facilities in order to obtain acceptable total and differential settlement values. This decision was based on the calculations of bearing capacity and foundation soil settlement, and the improvements will be carried out according to the following principles:

– Excavation of the existing terrain to -1.05 m below the expected elevation points of the foundation (foundation strips or foundation slabs). For the structures with spread footings for foundation, the excavation is carried out to -0.75 m.

– Foundation soil improvement by mechanical compaction at the elevation point of the bottom of the excavation.

– Laying geotextile at the bottom of the excavation.

– Backfilling of substitute rock material in a thickness of 70.0 cm with compaction (2 layers of 35.0 cm) under the structures with slabs or strips for foundation. Under the structures with spread footings for foundation, the substitute rock material is backfilled in a thickness of 40.0 cm with compaction (2 layers of 20.0 cm).

– Installation of a single layer of mechanically stabilized granular rock material (buffer) with granulation Ø 0-63 mm, thickness 30.0 cm with compaction.

– Installation of underlying concrete of compressive strength class C 16/20 in a thickness of 5.0 cm.

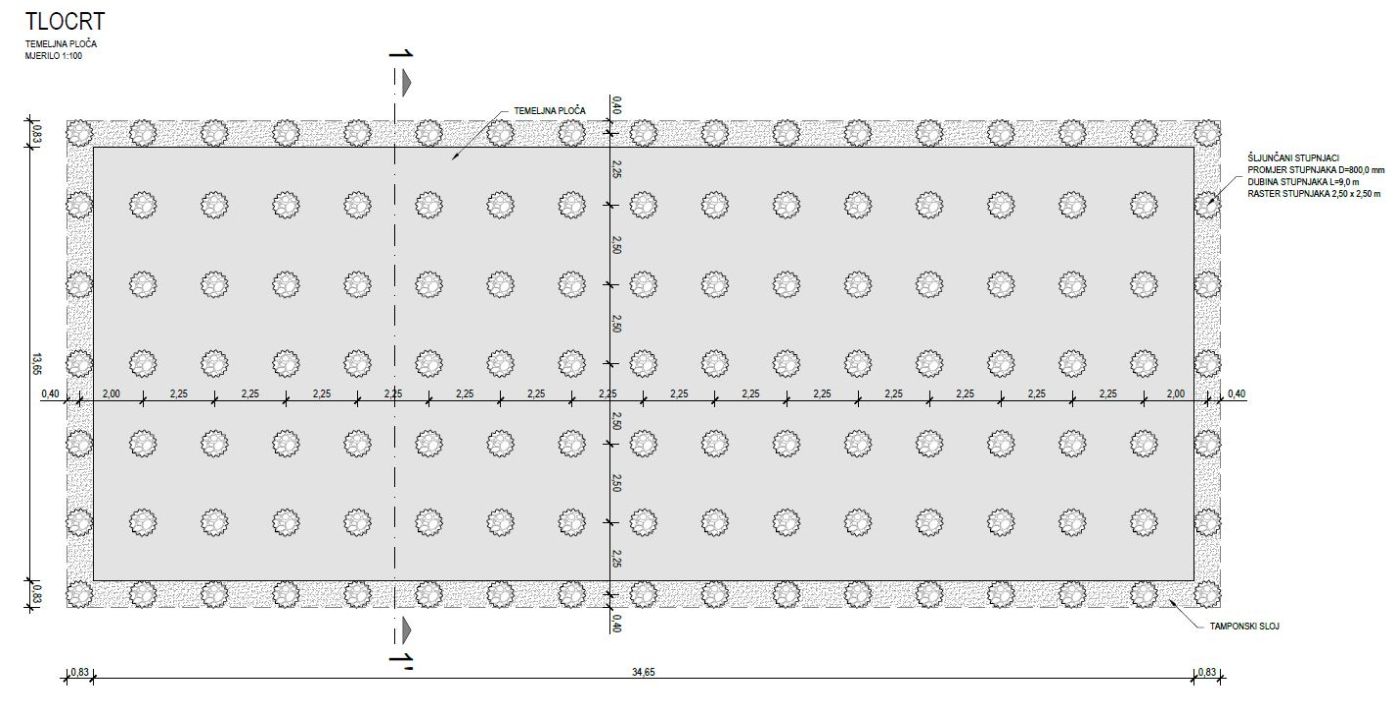

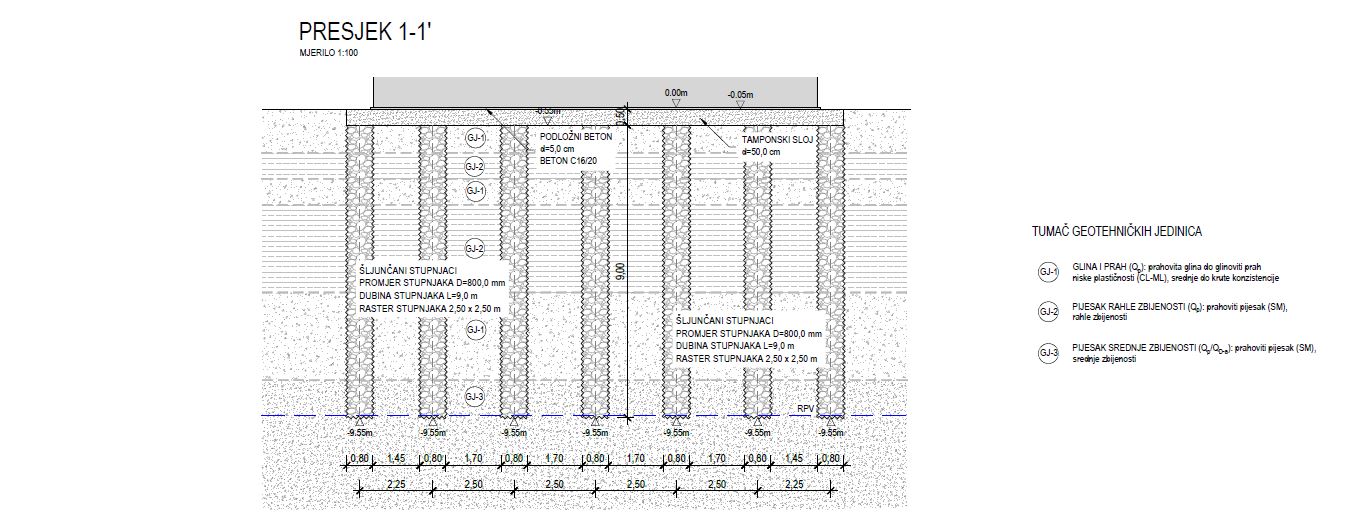

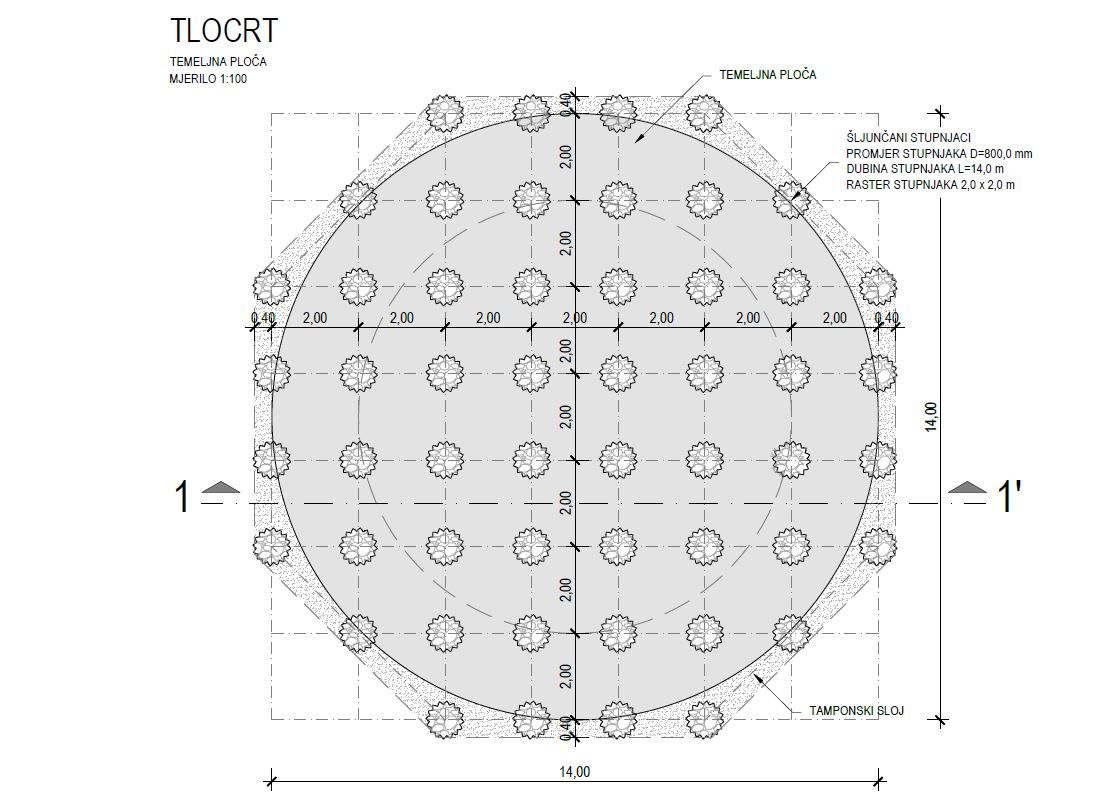

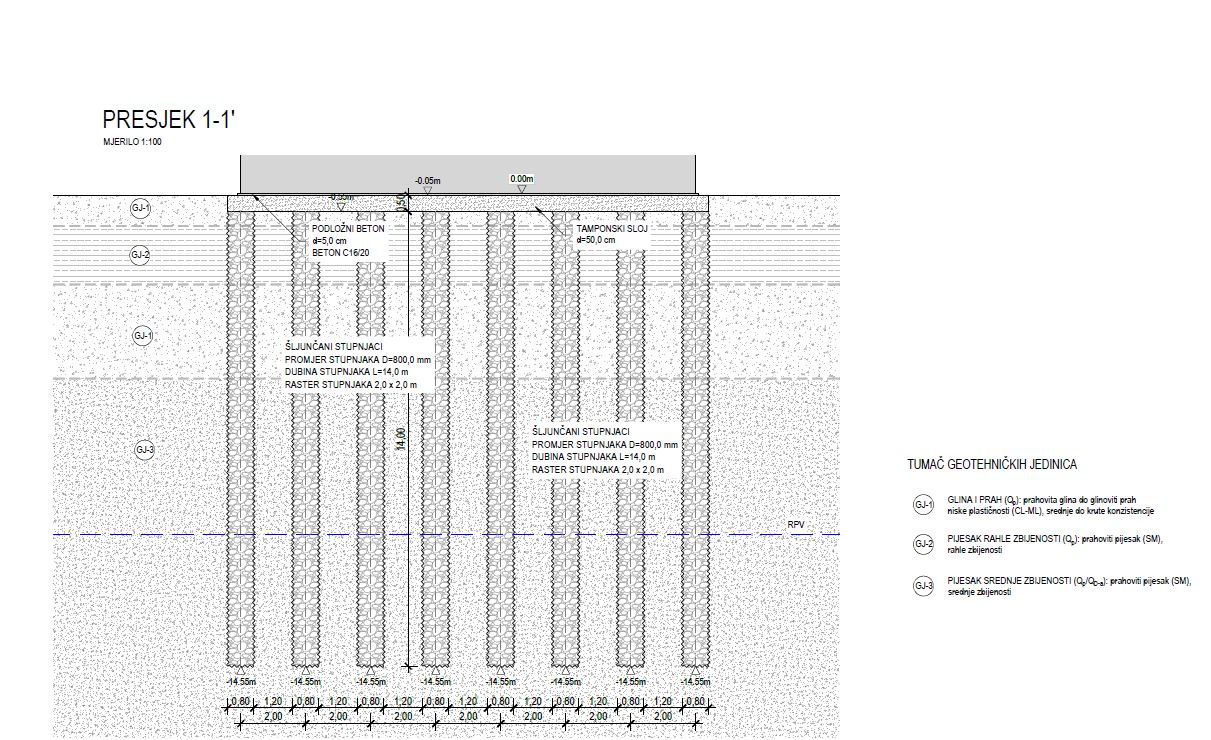

As for the administrative building and the hot water tank, the settlement values for the foundation slabs obtained initially were unacceptable. Because of this, soil improvement is planned by installing gravel columns with a diameter of D=800.0 mm and individual length of 9.0 m, in a grid 2.50 x 2.25 m for the administrative building and gravel columns with a diameter of D=800.0 mm and individual length of 14.0 m in a grid of 2.0 x 2.0 m for the hot water tank.

The gravel columns are installed using the deep vibro replacement technique, whereby by pressing the rock material into the softer soil, new load-bearing and highly permeable volumes are created in the form of piles.

A single layer of mechanically stabilized granulated rock material (buffer) of granulation Ø 0-63 mm and thickness 50.0 cm with compaction is laid above the elevation point at the top of the soil improved with gravel columns. A layer of concrete of compressive strength class C 16/20 in a thickness of 5.0 cm is laid atop the buffer, just like for all the other planned facilities.

Conclusion

Because of the significant dimensions and scope of the project, a large number of calculations of bearing capacity and foundation soil settlement were carried out. Soil parameters obtained during the detailed geotechnical investigations and testing were used in these calculations.

The calculations helped determine which facilities need additional soil improvements at deeper levels for their foundations and which can be planned with just the basic soil improvements. This decision was based on the dimensions of the facilities and the loads that they transfer to the foundation soil. Installing gravel columns represents a method of improving the mechanical characteristics and the drainage conditions of the foundation soil. Installing rock material (gravel or crushed rock) improves the mechanical properties of the foundation soil, specifically the strength parameters and the average compressibility modulus of the soil.

Read more: Foundation designs