Dynamic compaction

Good-quality compaction is highly significant for the proper relationship between the bearing capacity and deformation in connection with safety, usability, life span and maintenance of structures either lying on earth material or made of such material.

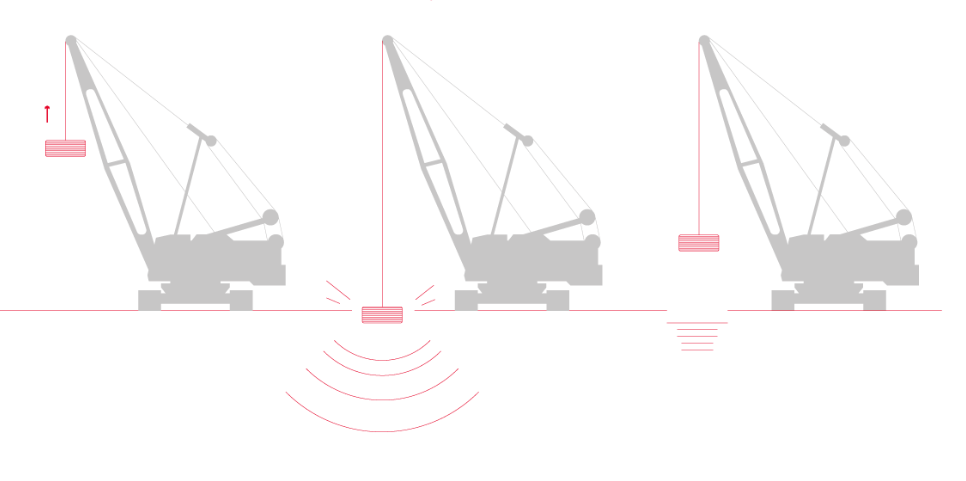

Dynamic compaction (DC), also known as dynamic deep compaction, is a ground improvement technique in which drop weight, typically made of steel, is lifted by a crane and repeatedly dropped onto the ground surface. Dynamic compaction has been used on numerous construction sites all over the world for various soil conditions and for a variety of applications such as roads, airports, large halls, etc.

Dynamic compaction utilizes the dynamic effect of high energy impacts caused by the drop weight. Steel weights weighing between 15 and 40 tons are dropped from a height of 10 to 40 meters. The purpose of this technique is to transmit high energy waves through a compressible soil layer to improve geotechnical properties of soil at greater depths.

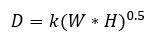

The depth of influence is related to the square root of the energy from a single drop (weight times the height of the drop) applied to the ground surface:

where:

D – maximum influence depth in meters beneath the ground surface

W – weight in metric tons (9 kN) of the object being dropped

H – drop height in meters above the ground surface.

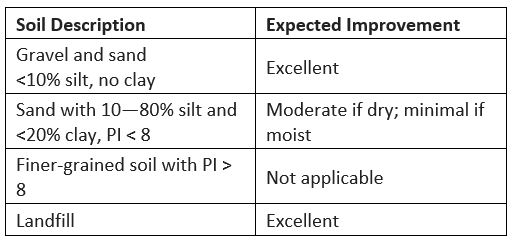

The constant k varies with soil type and is between 0.3 and 0.7, with lower values for finer-grained soils.

Even though the largest depth of improvement predicted by this method is in the upper two-thirds, the improvement gradually decreases until it reaches zero in the bottom third. The degree of improvement attained within this zone is increased by landing strikes repeatedly at the same spot.

(Source: https://www.menard-group.com/soil-expert-portfolio/dynamic-compaction)

This technique is most effective in permeable, granular soils, as cohesive soils tend to absorb the energy and limit the technique’s effectiveness.

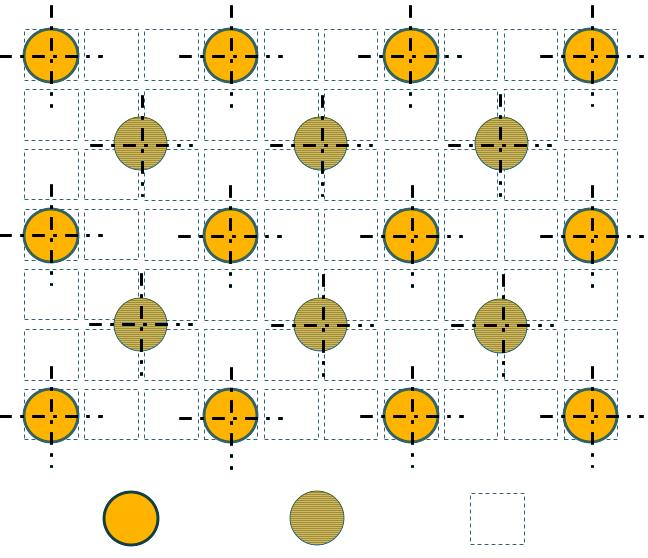

Done systematically in a rectangular or triangular pattern in 3 phases. The primary drop locations are normally laid out in a grid of 3.1 to 6.2 meters. Deeper layers are compacted at wider grid spacing and upper layers are compacted with closer grid spacing.

Spacing between impact points depends on:

- depth of compressible layer;

- permeability of soil;

- location of ground water level.

A clean, freely draining granular earth is often used to fill the craters left behind by the operation. Sandy soils can be treated by using a backfill made of sand. Finer-grained soils or landfills are frequently treated with a crushed stone backfill.

Advantages and limitations of dynamic compaction

Advantages of dynamic compaction:

– compacts large areas of loose granular fills;

– reduces the volume of landfill waste;

– increases in situ density and the voids are collapsed;

– increases bearing capacity;

– reduces post-construction settlements.

Limitations of dynamic compaction:

– expensive and time consuming;

– shock waves affect underground utilities in developed areas;

– the soil can be treated only up to 3 m away from underground installations;

– causes environmental pollution by making noise, gusts of air, vibrations.

The increase in pore pressure and localized liquefaction in some saturated soils cause a slower improvement of soil. The pore pressure dissipates during the rest period and results in an improved soil due to the reorganized soil structure. For the procedure to be successful, the groundwater table must be at least 1.8 meters below the working surface. Usually, this technique should not be carried out within 15 m of existing installations and 30 m from existing buildings.

Conclusion

Compaction is a complex process and a large number of factors should be taken into account in order to obtain a suitably compacted surface. Buildings founded on such improved soil proved significantly more resistant to seismic impacts than buildings standing on soil that was not improved by dynamic soil compaction/increase in density. The concept of dynamic compaction is simple, but experienced engineers and good planning are essential. In addition, the thorough understanding of soil strata prior to application and the maintenance of excellent control during all phases of the work is necessary.